Types of Aluminum Coating For Windows And Doors

Aluaugrd high performance system doors and windows are widely used in all building types, from high-end residential building to commercial, retail, hotels, hospitals and so on. Customized aesthetics, durability, cost-effective and non-corrosive properties are just some of the advantages that make aluminum a popular choice for architects and designers.

Although aluminum does not rust, it is easily oxidized when exposed to oxygen. Therefore, the need to protect and maintain the structural integrity of the material over the long life cycle of the material has given rise to aluminum coatings.

TYPES OF ALUMINUM COATINGS

Wood grain powder coating

Wood grain powder coating is an eco-friendly finish that has the appearance of traditional wood with the strength of aluminum. Unlike aluminum, real wood is likely to warp, split, or eventually rot, especially in harsh outdoor conditions. 2years warranty, advise to use for interior window and doors.

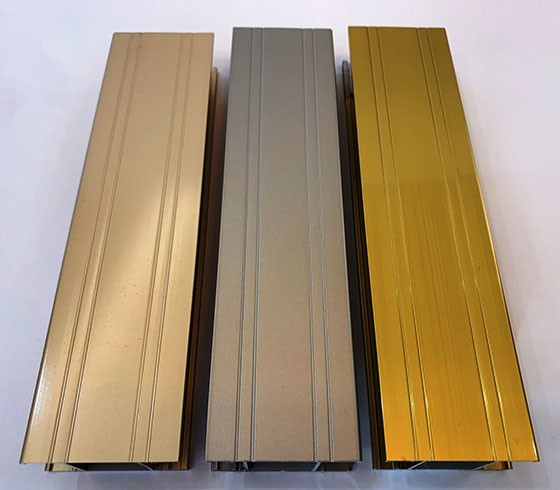

Electrophoresis treatment

Electrophoresis is an electrophoretic coating in the cathode and anode of the paint. Under voltage, the charged coating ions move to the cathode, and form an alkaline effect generated by the cathode surface, which is deposited on the surface. Aluminum type electrophoresis refers to the process of placing the extruded aluminum alloy in the electrophoresis tank, and forming a dense resin film layer after flowing. Electrophoretic aluminium profiles are very bright and have a mirror effect, which also improves corrosion resistance.Only a few color available, silver, gold, black, champagne, for project use.

Anodizing

Bronze anodized window anodizing process was first applied back in the 1920’s – it is an electrochemistry procedure that creates a protective aluminum oxide coating on the aluminum surface. A lifetime of such a protective finish varies depending on how thick is the anode coating.

Aluminum oxide is known for excellent durability and weather resistance, therefore it protects the metal quite well. The anodized coating can be either dyed into the desired colour or naturally produce bronze tones as a result of the diffraction phenomenon.A great advantage of the anodized coating is that it is an integral part of the base metal and therefore it does not peel or flake. The thicker the anode coating is, the more durable and more long-lasting it is.

Anodized colors are quite limited though. You may find anodized aluminum windows in the following finishes: clear, champagne, copper, light bronze, medium bronze, dark bronze, black.

If this suits your architectural requirements, then you should consider anodized aluminum windows with their durable, non-peeling, UV-resistant finish.Long service life, suitable for project use.

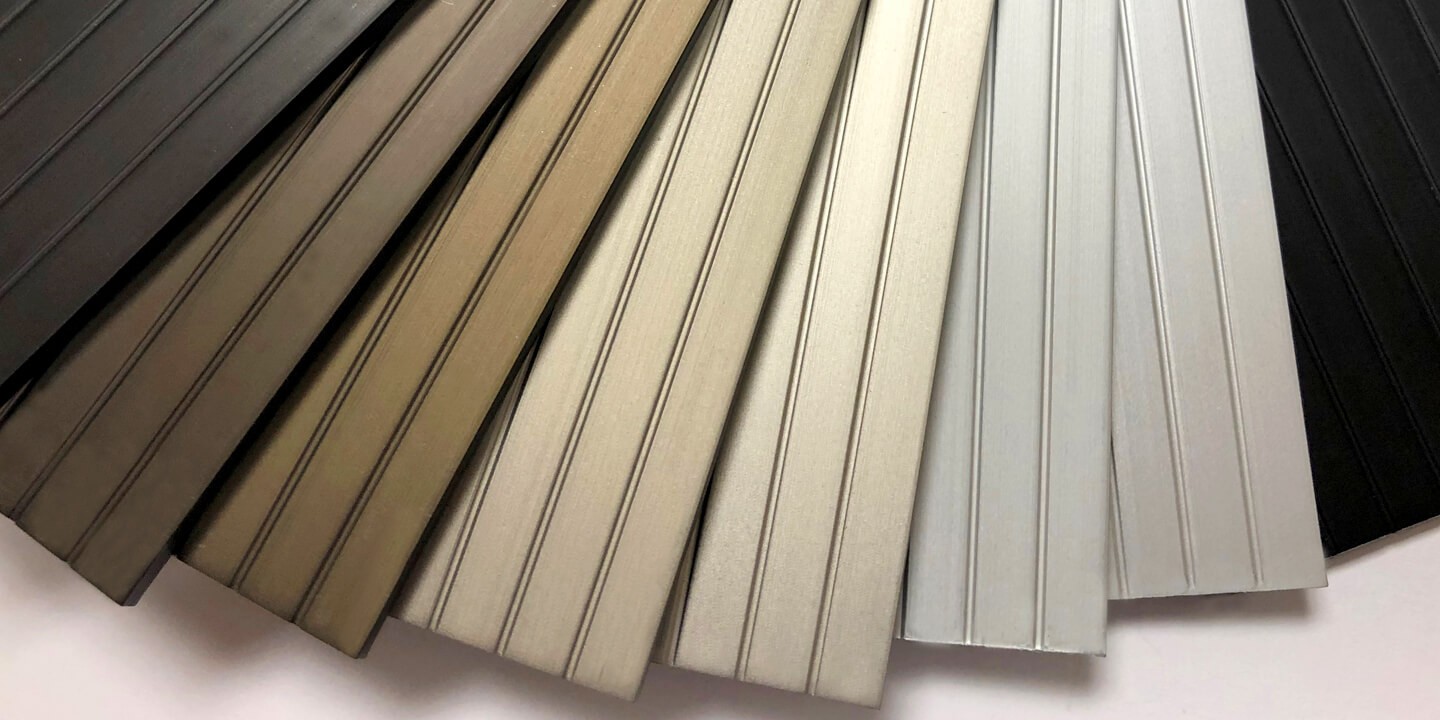

Electrostatic spraying

The powder coating is sprayed on the surface of the workpiece with an electrostatic powder device. Under the electrostatic device, the powder is evenly adsorbed on the surface of the workpiece to form a powder coating, and the powder coating has a high temperature baking flow to cure, and becomes each The effect of the final coating. The mechanical strength, adhesion, corrosion resistance and aging resistance of the spraying effect far exceed the previous spraying process.Only a few color available, silver, gold, black, champagne, for project use.

Fluorocarbon

Fluorocarbon spraying is electrostatic spraying and also a liquid spraying method. The fluorocarbon spray coating used is a coating made of polyvinyl fluoride vinyl resin as alkali or metallic aluminum powder as color. Suspended and semi-suspended, preprocessing and spraying of suspended aluminum alloys, suspended during curing. Excellent fluorocarbon coatings have metallic luster, unique and unique three-dimensional sense.10 years warranty for high end project.